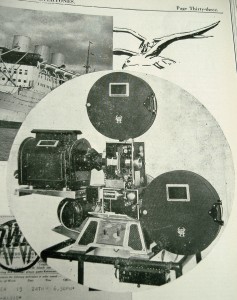

The C&W Raycophone Portable with the new C&W P5 projector head July 20 1932

By May 24 1933, there was now 69 C&W “Junior” fitted Raycophone portable projectors sold. By January 1934 these portables were being installed and used many hospitals and private homes in Sydney.

By November 1934 it is reported that 784 C&W projectors were now in use in Australia theatres

Advertisement and Photographs

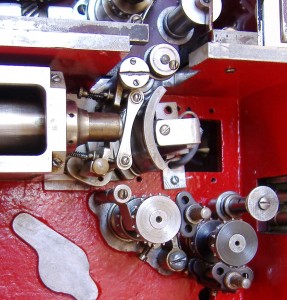

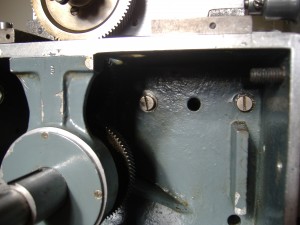

Assembling the Raycophone Portable Sound Head No.182

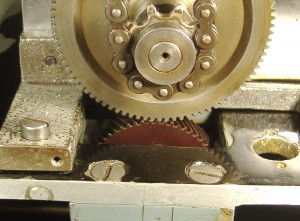

C&W P5 Raycophone Flywheel

Insert fixing screws just nip them up and check the messing again by carefully rotating the flywheel in a forward direction

If all’s well tighten up the mounting crews

Turn on the motor switch and let the projector run have your finger on the switch just in case, listen closely to the sound of the meshing of the gears

A very light fizzing noise? Any more than that investigate, a grinding noise stop!